CAPABILITIES

We invite you to discover OUR varied services -

- MANUFACTURING

- ENGINEERING

- ASSEMBLY & TESTING

- INSPECTION TECHNOLOGY

- FINISHING & POSTPRODUCTION PROCESSES

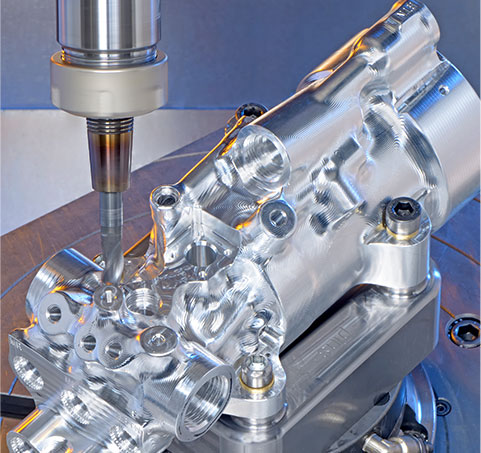

MANUFACTURING

- Milling, turning (tolerances up to +/- 0.0001")

- 5-axis mill-turn machining centers

- Manufactured components ( size 0.030" to 15”)

- Precision honing and lapping

- Surface grinding

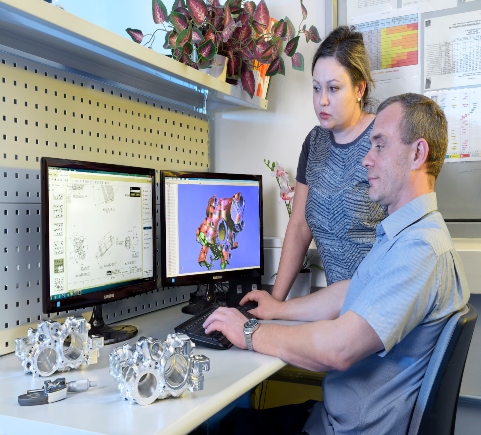

ENGINEERING

- Design review

- Cost reduction analysis

ASSEMBLY &

TESTING

- Bearings & Bushings assembly

- Lee Plugs assembly

- Rosan® fitting assembly

- Pressure tests

- Flow tests

- Valve seat & leak inspection

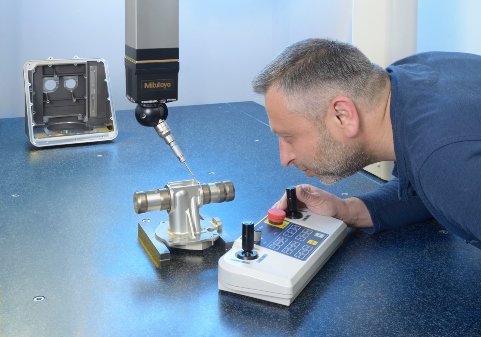

INSPECTION

TECHNOLOGY

- Programmable Mitutoyo CMMs

- Single-port air-bore gauges

- Surfometers

- Microscopes

- Bore scopes

- Digital and Optical comparators

- Hardness testing

FINISHING &

POSTPRODUCTION

PROCESSES

- Cosmetic blasting *

- Tumble finishing *

- Laser marking

- Anodizing

- Heat treating

- Plating (nickel, chrome, zinc, others)

- Grinding

- Honing *

- Brazing

- Passivation

- Electropolishing

- Broaching *

- Electrical Discharge Machining (EDM)

- Non-Destructive Testing (NDT)

*Performed in house

We use only certified, qualified subcontractors for specialized finishing processes.

WHY MOKED

- AS9100C, ISO 9001 certified

- Lean production practices

- IOT based Manufacturing execution (MES) system

- Supply chain management (SCM) system

- Quality management system (QMS) software

- Process validation protocols

- Strategic business planning and practices

- Clean production area, with dedicated testing laboratory - designed for efficiency